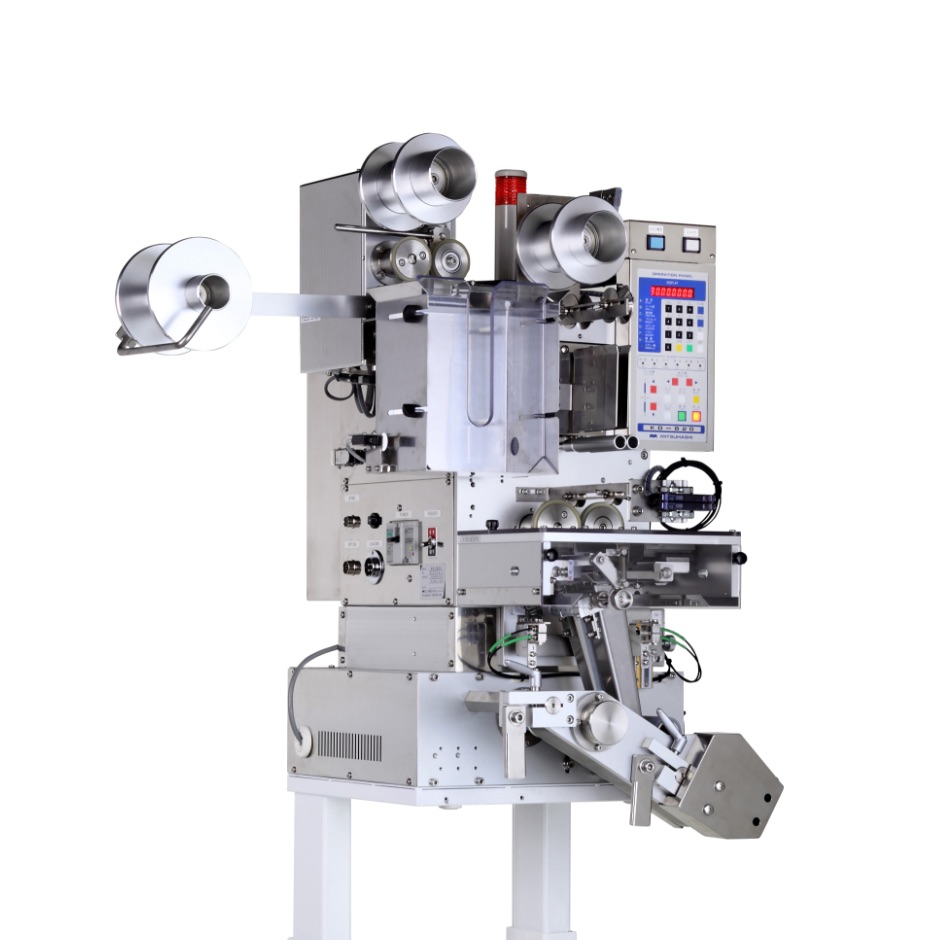

KD-820&KK-360

Pouch dispenser with fixed-position loading device

The device consistently cuts continuous packaging pouches into one pouch (multiple pouch units are also possible) at a time, and loads them by automatically following the packaging device’s conveyor speed. The device can be used for various types of pouches including powders, drying agents, oxygen absorbers and liquids.

Drawing

Labor saving effects

Manual work

approx. 30 pouchesAfter installing the device

approx. 200 pouches/min

Features

- Feeding capacity: 200 pouches/min

- Pouches are transferred on the conveyor belt and loaded by automatically following the packaging device’s conveyor transport speed.

- Even when the conveyor transport speed of the packaging device changes, the pouch loading position will remain fixed.

- Be with an automatic ejector (optionable) , it is for save the labors.

- The belt transport unit can be easily removed, enabling easy cleaning and maintenance.

Specification

| Feeding capacity | 200 pouches/min (maximum) <With 70mm pouch length> *The longer the pitch of the pouch length is, the lower the capacity will become. *However, maximum speed capacity does changeable depending on kind of sachet film and packed material in the sachet. |

|---|---|

| Pouch specification |

Width 30 – 100mm Length 30 – 150mm Thickness 7mm (maximum) |

| Power supply | 3φ AC200/220V 50/60Hz 1.5kVA |

| Weight | Approx. 45kg |