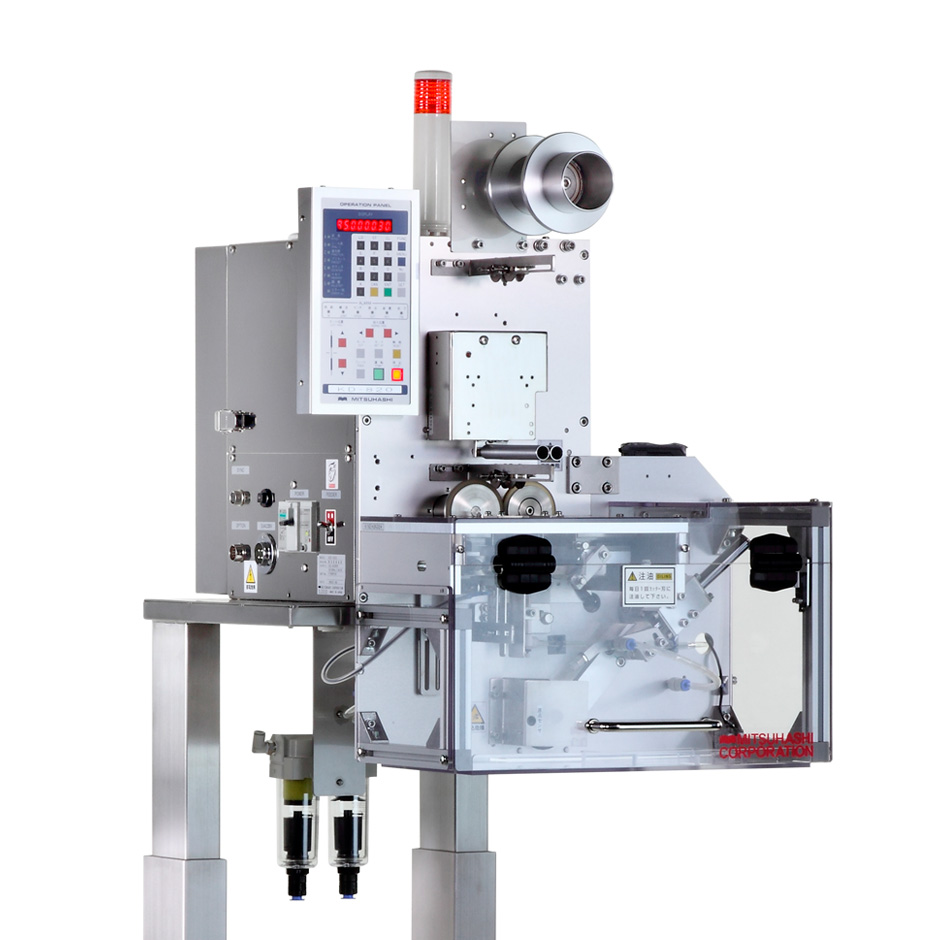

KD-820&LV-100

Adsorption-type pouch dispenser

The device consistently cuts continuous packaging pouches into one pouch (multiple pouch units are also possible) at a time, and adsorbs/loads them in place on a conveyor line at a high speed. The device can be used for various types of pouches including powders, drying agents, oxygen absorbers and liquids.

Drawing

Catalog

Labor saving effects

Manual work

approx. 30 pouches/minAfter installing the device

approx. 100 pouches/min

Features

- Feeding capacity: 100 pouches/min

- Gently loads pouches to a fixed position at an accurate timing by adopting an AC servo motor drive.

- It cuts and adsorbs simultaneously, so the pouches can be loaded in the same position each time.

- Optimal for right-angle loading and attaching/loading to the packaging machine conveyor.

- By combining this device with hot melt coating equipment or the TM-200 (double-sided tape applicator,) attachment to packaging film can be performed accurately.

Specification

| Feeding capacity | 100 pouches/min (maximum) *The longer the pitch of the pouch length is, the lower the capacity will become. *The maximum capacity will vary depending on the conditions of the packaging materials and contents. |

|---|---|

| Pouch specification |

Width 20 – 70mm Length 25 – 90mm Thickness 1 – 10mm |

| Power supply | 3φ AC200V 50/60Hz 1.5kVA |

| Weight | Approx. 40kg |

| Air source | 0.5MPa 50L/min (ANR) dry air |