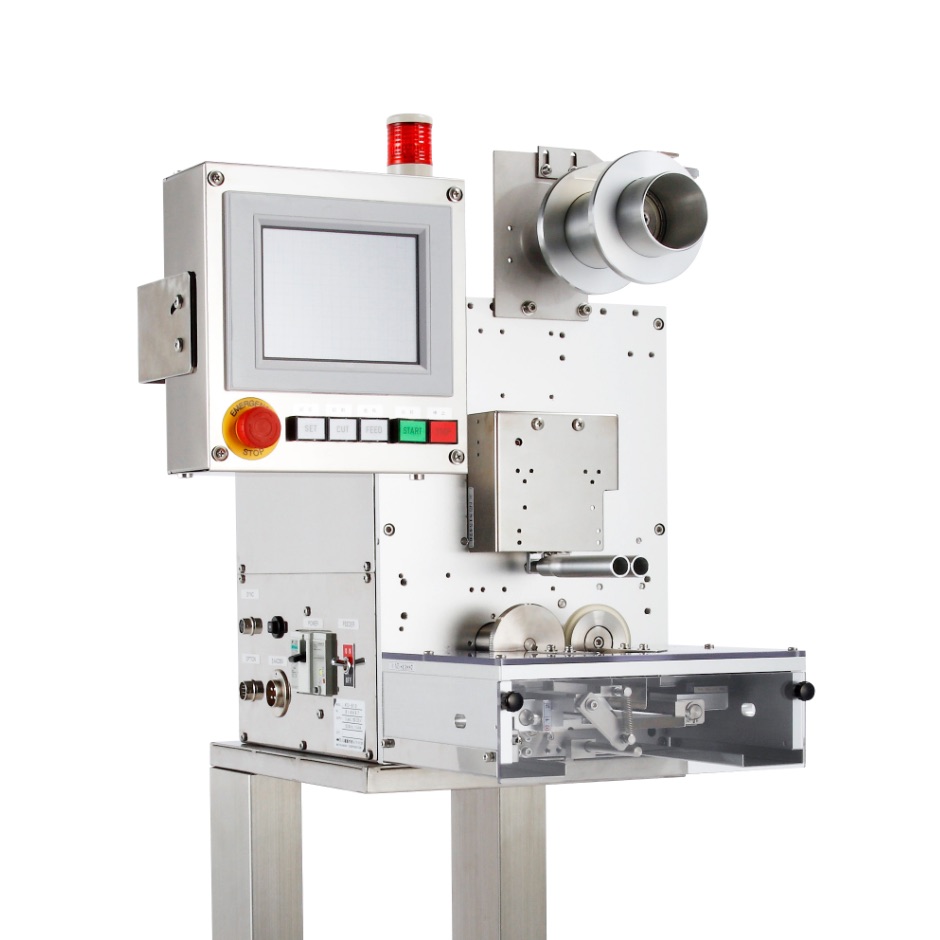

KD-820 Touch Panel Control Board

The pouch dispenser can be operated on the touch panel. The operation method is simple and error displays are clear so the device can be used even more easily.

Drawing

Features

- Easy operation with text displays. There is no need to remember the error codes or data numbers.

- Equipped with an easy-to-see 5.7-inch color touch panel.

- Switchable language settings. Compatible with many languages including Japanese, English, Chinese, Taiwanese, and Korean, etc.

- Prevents incorrect product category selection by registering the product names in advance.

- The alarm history function (maximum 1,024 alarms) is added.

Specifications

| Power supply | DC24V *Supplied from the KD unit. No need for a separate power supply. |

|---|---|

| Weight | Approx. 3kg |

| Operating environment | 0℃ to 40℃, humidity 80% RH or below (no condensation) |